A visit to mudhouse in rural St Andrew

Nestled in Irish Town, St Andrew, on a multi-crop farm is a sustainable farmhouse built from mainly natural materials.

The Mudhouse is representative of a modern design using a traditional construction method, wattle and daub.

It is affectionately referred to as ‘a IT dat’, the response of someone who saw a picture of the house shortly after completion, but now, ‘IT’ represents Irish Town.

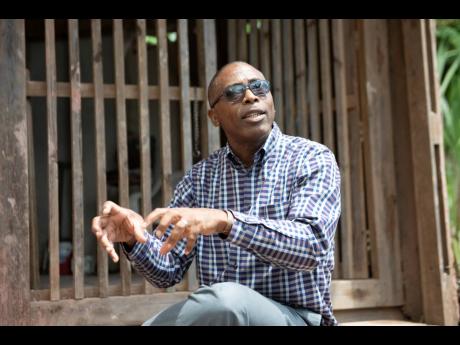

Dean of the Faculty of the Built Environment at the University of Technology, Dr Garfield Young, described the built environment as “the human conceptualised, created and maintained spaces in which we live, work and recreate”.

He explained that a team from Touraterre, a French collaborative, initiated the idea of a competition for a raw earth project with modern architecture.

Five teams were created between the universities and the winning guest house design was determined by a panel of adjudicators.

Young said the university made arrangements for it to be built on farmland owned by an 88-year-old farmer.

Ricardo Lucien, a fourth-year Trinidadian student, was integral to advancing the project which commenced in May 2016.

“I found it interesting because it is applying what you learn in school in a practical nature. The main materials were mud, coconut husk and some of the modern materials would be the mesh, the American pitch ply as the frame and also the zinc,” Lucien explained.

“We mixed the mud together with some limestone and also a bit of sand that we got from the nearby stream and with the wattle and daub technique, we created the outer skin,” said Lucien.

The red pigment from Annatto, made from the seeds of the achiote tree, was mixed with limestone for the finishing coral colour on the outside while a layer of white lime combined with mud was plastered on the inside.

At the entrance of the house is an oven made from similar materials which Lucien said was built afterwards.

“It serves two purposes – the main purpose is to cook and in the night here is actually cold so it creates a heating system,” Lucien said.

The house overlooks the city of Kingston and has a circular design with a swirl that provides a private space in the inner section.

Conrad and other farmers have used the farmhouse for storage, as a rest area and shelter from the rain.

With the help of steps built by the students, it is a 10-minute trek from the Irish Town main road.

“It’s cool. I stay here until late in the evenings and I use a candle or a lamp. It’s part of the natural setting – no electricity but electricity isn’t far away,” the farmer said.

The dean explained that it was built over a three-year period with breaks in-between.

The farmhouse was built at a cost of $600,000 – “for the material we had to buy because it has a wood frame and there are five piles foundation made from concrete.”

“It was an inexpensive project and it could be cheaper if we had far greater volunteers,” Young said.

Coconut husk was the fibrous material used in the construction of the Mudhouse but the dean noted that the faculty has been looking into research of hempcrete which is a strain of marijuana that has “very strong fibres”.

He added that bamboo leaves, which are popular in the area, could also be a substitute.

Dr Patricia Green was the head of the faculty when the project began in 2016.

She spoke with much enthusiasm about the method which she described as “traditional, vernacular architecture”.

“The daub is when you mix up the mud, put some secret ingredient in there like cow dung as a binding agent and then you add the fibrous material and then daub it. This means that you use your hand, splash it on the wattle and keep rubbing it in – that’s the daub,” she explained.

Green said the structure is resistant to hurricanes and earthquakes and should it suffer any damage, maintenance is possible.

“What we have to do is to make sure that when we build it, we tie all the timber together ... . It requires maintenance, but instead of going to the hardware shop, you go out and you get the things from the land – [and repeat the latter stage of wattle and daub].”

As to the next step for the Mudhouse, there are plans to have workshops for people interested in traditional construction methods.