Expert downplays pollution risk in Cockpit Country

WESTERN BUREAU:

Bauxite operations by Noranda in Special Mining Lease (SML) 173 of the Cockpit Country will not cause above-ground and subsurface water pollution, environmental consultant Dr Conrad Douglas has said.

Douglas said, during a consultation session Tuesday on an environmental impact assessment (EIA) on the ecologically sensitive area, that many Jamaicans have been conflating bauxite mining with alumina production, an entirely different process that uses caustic soda.

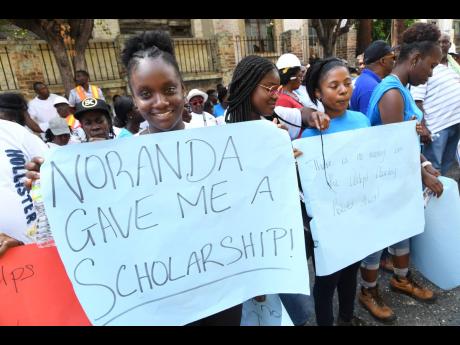

Prospective mining in the area has been at the centre of a dispute between bauxite interests and environmental and community groups.

“Let me state very, very clearly, or as clearly as I can. Noranda will not be engaged in the production of alumina,” he stressed, in response to concerns raised about the possibility of water contamination similar to what took place at the bauxite works at Ewarton, St Catherine.

According to Douglas, the alumina plant in Ewarton uses an extractive, hydrometallurgical process that involves the use of caustic soda, a corrosive chemical also known as sodium hydroxide, to extract the aluminium values.

Douglas said that caustic soda, in the past, had “the potential to leak into the underground” from mud lakes operated by bauxite companies - a problem that, he said, has been corrected through the invention of a dry mud-stacking technique.

Dry mud stacking, now a global best practice, is the most commonly used method for red mud disposal at large alumina refineries worldwide.

The process reduces the potential for caustic soda to leak into the surrounding environment, and maximises the recovery of caustic soda and alumina.

Douglas, whose firm authored an EIA on the SML 173 works, also came to the defence of the other bauxite companies, arguing that the misconception about their mud lakes could also place them under unwarranted scrutiny.

“We don’t want to make the other alumina companies culpable either, because they have taken steps to contain those residues,” he said.