Tailors, dressmakers wilt under pressure of uniform orders

As the new school year beckons, tailors and seamstresses are contending with the mounting pressure from last-minute back-to-school orders as parents struggle with finances.

Surging prices for food and other commodities have eroded household incomes all year, but the recent 0.7 per cent decline in point-to-point inflation may offer late summer solace.

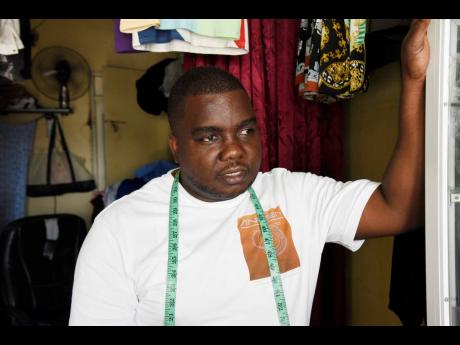

Allan Lewis, who has been sewing garments for 25 years, says the last-minute demands for tunics and khaki shirts and pants have been chaotic.

“I have to be out here most nights until about 3 o’clock some time,” said Lewis, who operates at the corner of Belmore Lane and Brunswick Street.

Running on low fumes, Lewis said that he returns to his workstation by 9 a.m. the next day to begin the process all over again.

Lewis admitted that he felt “out of practice” with the manufacturing of school uniforms with classroom doors being shuttered for almost two years because of the coronavirus pandemic.

The first full-scale start to an academic year since 2019 has now pushed Lewis to readjust to churning out orders rapidly.

And like most tailors, Lewis is struggling with a backlog in his production schedule.

“The school season now very hectic. Not even know how I’m going to put through everything for this week,” he said, despite employing a second set of hands to help with the workload.

Part-time dressmaker Tamara Edwards said that most parents have been turning up late to put in their orders, causing pressure to escalate.

Tardy requests, she said, have been blamed on tighter home budgets. That has set off alarm bells with her already busy schedule.

“I have to refuse some of the orders ... . I got full up by the middle part of August [from] basic, primary, tertiary uniforms [to be] done,” she said.

Edwards said the lead-up to the new academic year has been a welcome difference to the pandemic crisis era of 2020 and 2021.

“Last year, I never get so much, maybe get one or two, but this year it more better than last year,” she said of the uniform orders.

The dressmaker said that the mass-production ready-made uniform industry has not impacted her business, but the buoyant demand has caused adjustments to her working hours.

“It has changed a lot ... . Sometimes I get like a three, four hours sleep. For this week, [it’s] really tight, so I’m not sure what time I’ll be getting rest,” she told The Gleaner.

For more than 20 years, Pansy Bingham, who took over from her apprentice master, worked at the shop on Adelaide Street in Spanish Town, St Catherine.

Though some clients turned up with cloth from as early as July, she has not been spared by the pressures of 2022.

Bingham said that she occasionally starts sewing at home before heading to the store in the mornings to complete the orders. She has even had to drink energy drinks just to stay awake.

“Other people come and I have to turn them back and send them to a tailor around the corner, because I cannot take anymore,” she said, confessing that she was also at fault for not being quick at stitchwork.

She completes up to three uniforms per day and some khaki shirts.

Although some parents bring enough material for the construction of five uniforms, Bingham said she might only be able to prepare two sets and return the remaining three in September.

“I have to work very hard this week ... because this is the last week before school, so I have to put in extra time,” Bingham said.